Smart packaging

It began with a vision involving Charles Darwin’s evolution theory, and ended with an AI-driven solution set to change machine tool packaging as we know it. When Sandvik Coromant launches its new solution, optimized packaging will lead to major cost-savings and vastly lower CO2 emissions.

Maria Rajabzadeh NamaghiIn the summer of 2019, Maria Rajabzadeh Namaghi, a 33-year-old R&D engineer and system developer from Iran, was sitting in her office in Sandviken, Sweden working on the next generation of Sandvik Coromant product packaging solutions. She had a tall order: to ensure the packages selected would be as small and lean as possible to not only cut material costs but to help the Sandvik Group reduce its overall carbon footprint.

Maria Rajabzadeh NamaghiIn the summer of 2019, Maria Rajabzadeh Namaghi, a 33-year-old R&D engineer and system developer from Iran, was sitting in her office in Sandviken, Sweden working on the next generation of Sandvik Coromant product packaging solutions. She had a tall order: to ensure the packages selected would be as small and lean as possible to not only cut material costs but to help the Sandvik Group reduce its overall carbon footprint.

I was really excited, I couldn’t wait to tell my colleagues about it when they were back from vacation

Although Rajabzadeh Namaghi had already found a solution based on traditional computer programming, she couldn’t kick the nagging feeling that something was missing. “The solution wasn’t flexible enough. It was customized for a certain type of packages, and it wouldn’t work for new types of packages,” she recalls.

Then, as she let her thoughts wander through the deserted office landscape, it suddenly hit her: “What if I applied genetic algorithms using Artificial Intelligence?” A genetic algorithm is an AI-based problem search process based on Charles Darwin’s evolution theory. Just like in nature, the algorithm evolves through the generations, allowing for smarter and better solutions to develop with every cycle. After spending a few days putting her theory to the test, Rajabzadeh Namaghi knew she was onto something big.

Size or shape doesn’t matter

“I was really excited, I couldn’t wait to tell my colleagues about it when they were back from vacation,” she recalls, noting that although the genetic algorithm isn’t something new in itself, she had never heard of it being applied to packaging solutions in this manner before.

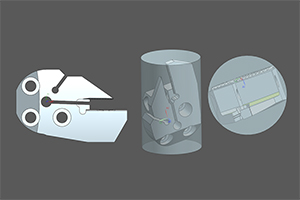

AI-based packaging solution finds the smallest possible packaging for a tool.

AI-based packaging solution finds the smallest possible packaging for a tool.

“The way it works is that whatever you might need to put in a package - whether something small like a tool or something big like a bicycle – the application will find you the smallest possible package to fit it into. The size or geometrical shape of what’s being packed doesn’t matter,” she says and explains how the Package Selector Application (PSA) identifies the most critical points of an object by analyzing a CAD-based model of it in 3D.

The AI algorithm then takes over to work out the object’s rotation, and from there, the application is able to not only recommend the smallest possible packaging for it but also how to fit the object into the selected packaging.

You can fit more into a shipment and therefore reduce the fuel consumption

Aside from contributing to lower costs when it comes to packaging materials, transport and storage, the ability to always select the smallest possible package will also help reduce CO2 emissions. “The smaller packages you use, the less package material you waste. And in terms of transport, smaller packages take up less space, and you can fit more into a shipment and therefore reduce the fuel consumption,” Rajabzadeh Namaghi says.

Live in 2021

Samir Balic, Product Manager Packaging and Labelling at Sandvik Coromant, says the application, which is scheduled to go live in the second half of 2021, will automate the packaging selection process “from start to finish.”

“The product designers will get a tool added to their CAD-programs, and with the simple push of a button, they will be able to film the tool they have just created and it will be matched with the most suitable packaging – even before the tool has been physically created.”

Want to know more about Sandvik Coromant?

We make the shift – advancing the world through engineering

Through our diverse teams, strong culture and leading-edge skills we enhance productivity, efficiency and sustainability in a world that needs to evolve. Our role is clear – through every action, every day, we make the shift and advance the world through engineering.